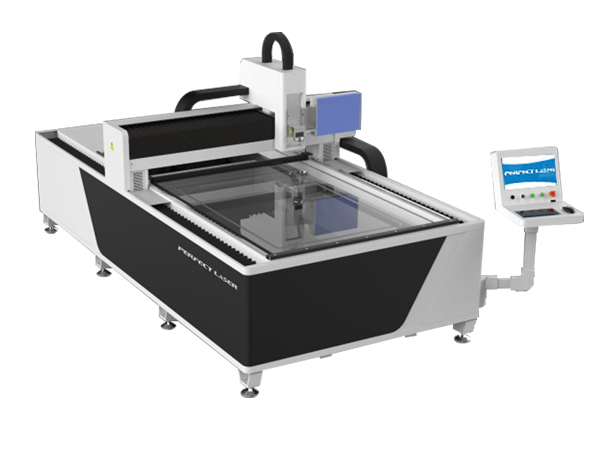

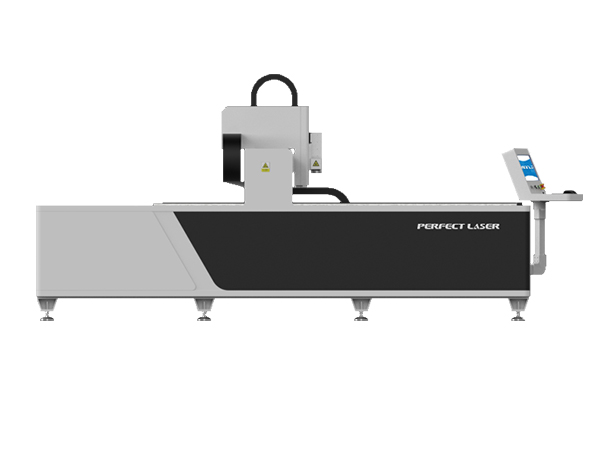

Model: PEDB-190

The laser glass sanding machine utilizes cutting-edge laser technology, precisely controlling the energy and focus of the laser beam to achieve highly efficient material surface processing. It surpasses traditional sandblasting methods by addressing issues such as complex procedures, pollution, and low yield rates.

Featuring a non-contact processing approach, it can create intricate and diverse patterns with a single click. The laser glass sanding machine integrates functions such as drilling and film removal, offering versatile capabilities that significantly reduce business costs. Environmentally friendly and highly efficient, it sets a new standard for intelligent glass sandblasting in the modern era.

1. High Efficiency and Energy Savings

The laser glass sandblasting machine features a premium MOPA fiber laser, delivering exceptional precision and speed. Its compact size and low power consumption strike the perfect balance between high performance and eco-friendliness.

2. Simplified Workflow

The laser glass sandblasting machine uses a laser processing technology, completing product processing in a single step, which effectively improves production efficiency and flexibility.

3. Large Processing Area

With a working area of up to 2.5m x 1.6m, it supports custom sizes to meet diverse smart mirror production needs.

4. Stable and Reliable Operation

Designed for 24/7 continuous use, it ensures consistent performance with a maintenance-free design, zero consumables.

5. Versatile Processing and Customization

From silver mirrors and aluminum mirrors to eco-friendly glass, the laser glass sandblasting machine supports a wide range of materials. It offers personalized solutions with features like automated loading and unloading, multi-station operation, visual positioning, and modular configuration—perfect for fully automated, unattended mass production tailored to unique customer needs.

The laser glass sandblasting machines are widely used in construction, automobiles, daily necessities, home furnishings, electronics, instruments and other fields.

Product name | Mirror Laser Sandblasting Drilling Paint Removing Machine |

Laser type | Anti-high reflection fiber laser source |

Laser power | 120W/200W optional |

Laser wavelength | 1064nm |

How it works | Manual loading, automatic processing |

Processing time | Depends on the product |

XY equipment effective travel | 2500*1600mm can be customized |

Drilling size | φ1-50mm |

Processing accuracy | ±0.03mm, no splicing marks |

Film removal speed | 0.5m/min, line width 3mm |

Sand blasting speed | 0-40m/min |

Processing thickness | 3-8mm |

Processing product size | Maximum 2500 * 1600mm |

Laser system cooling method | Water Cooling |

Dust collection system | Customized hole dust extraction structure |

System gas | 0.6-0.8MPa |

System power consumption | AC220V 50/60HZ |

Overall dimensions | 2480x3800x1785mm |

Machine weight | ≤2T |

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net