Model: PEG-7015

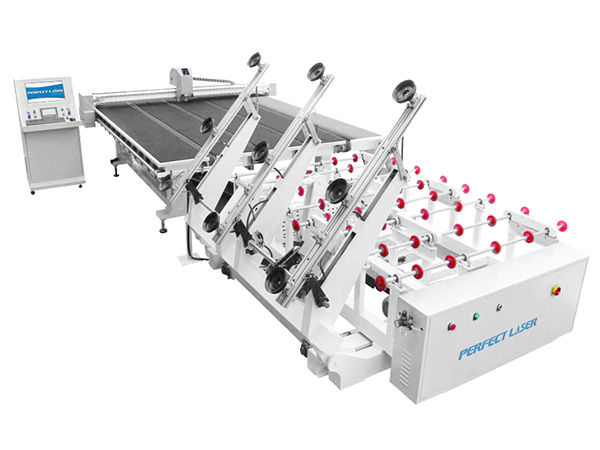

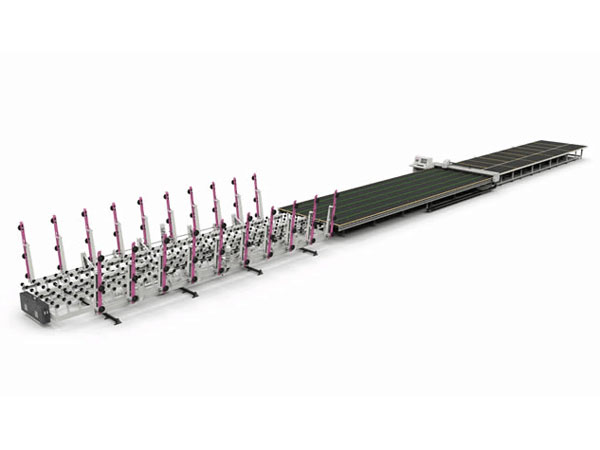

Introducing Italian technology, adopting international processing technology, Perfect Laser launches high-efficiency automatic large glass cutter for glass cutting. The whole heavy duty glass cutter system consists of single-turn single-station automatic glass lifting and loading table, automatic glass cutting machine, and gas floating splitting stage. The automatic glass cutting full solutions can support customer customization, and the glass cutter china can realize the automatic glass cutting in production lines.

The glass lifting table of this large glass cutter adopts imported vacuum pump, equipped with PLC and imported electrical components. The glass lifting time is 40-60 seconds (adjustable), the thickness of the lifting piece is 3-19mm, the operation is stable.

The heavy duty glass cutter adopts imported servo motor and CNC controller. Through computer CAD drawing, the glass cutter china can realize all kinds of glass optimized cutting, which is more convenient to operate and more stable in performance.

Glass lifting and loading table of large glass cutter production line

1) Flip mode: mechanical flip, fast running speed, stable operation. The double-turnover transmission chain protection ensures safe and reliable rollover process.

2) Flip angle: 95-98 degrees adjustable. It can meet the glass frame on various angles.

3) Suction depth: special rod expansion mechanism, the suction cup can be extended to 150mm, which can meet the depth of 700mm. It can be directly loaded from the iron frame without any auxiliary frame.

4) Induction device: Two sets of glass photoelectric sensors (one set, one set of spare) can be used to effectively prevent safety accidents caused by induction failure. The equipment is safer, more stable and reliable.

5) Lifting device: The unique connecting rod lifting device ensures that the lifting movements are synchronized and eliminates the defects of unsynchronized lifting. The safety of the glass can be guaranteed.

6) Adsorption device: The suction cup adopts double-layer adsorption structure (two layers inside and outside), and the suction piece is more firm, which eliminates the defect of adsorption and leakage caused by the outer layer of the suction cup.

Automatic cutting machine of heavy duty glass cutter

1) Main frame: The main frame ensures the table surface won’t be deformed and the parallelism is good.

2) Cutting knife holder: The cutting head can be rotated for 360 degrees, and the upper and lower cutting can cut any straight line and various shaped glass.

3) Working platform: Adopts imported waterproof high density panel. It is effective against moisture.

4) Felt: Adopts imported industrial felt (fiber and wool) has good flatness and anti-static, reducing glass scratches.

5) Oil supply mode: pneumatic automatic oil injection, and synchronization with the lower knife. Double oil circuit control, can use kerosene and cutting oil at the same time.

6) Conveying device: automatic feeding by belt.

This glass cutter china is suitable for the cutting of various linear and special-shaped glass such as electrical appliances, furniture, building curtain wall, hollow laminated rubber and solar glass.

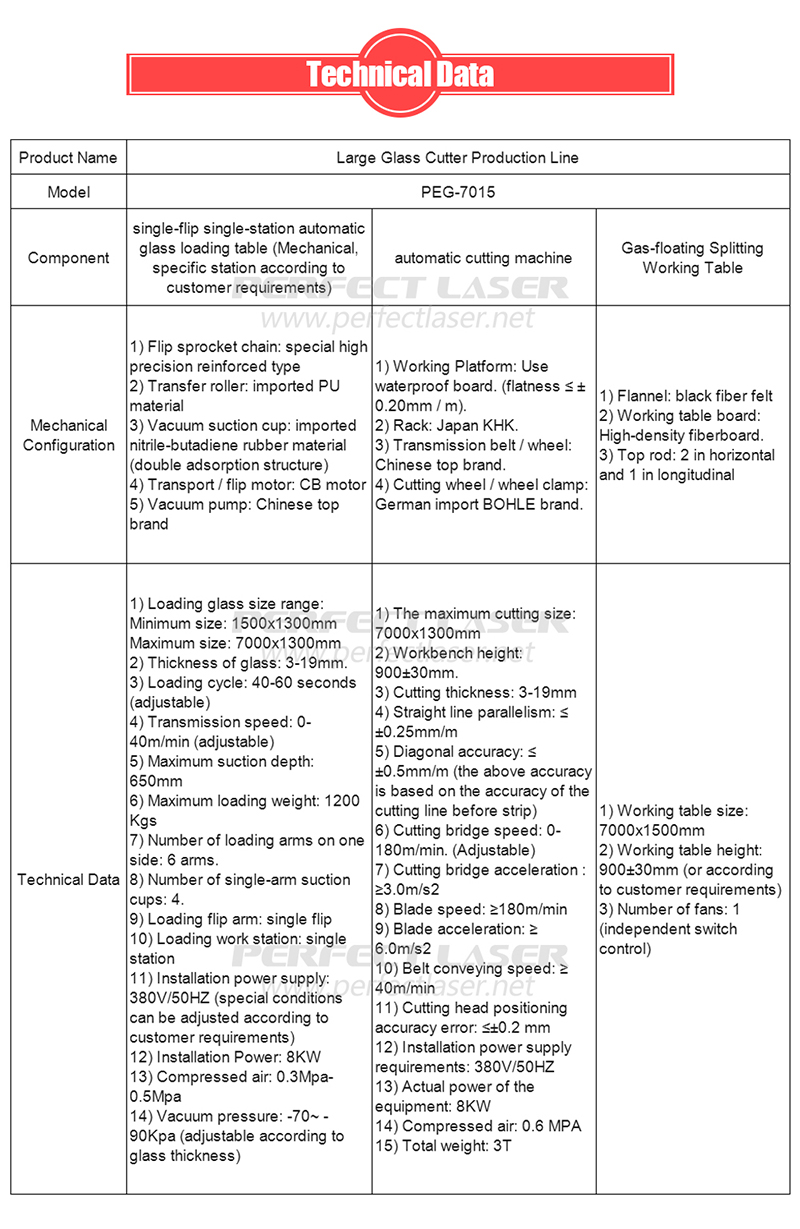

Product Name | Large Glass Cutter Production Line | ||

Model | PEG-7015 | ||

Component | single-flip single-station automatic glass loading table (Mechanical, specific station according to customer requirements) | automatic cutting machine | Gas-floating Splitting Working Table |

Mechanical Configuration | 1) Flip sprocket chain: special high precision reinforced type 2) Transfer roller: imported PU material 3) Vacuum suction cup: imported nitrile-butadiene rubber material (double adsorption structure) 4) Transport / flip motor: CB motor 5) Vacuum pump: Chinese top brand | 1) Working Platform: Use waterproof board. (flatness ≤ ± 0.20mm / m). 2) Rack: Japan KHK. 3) Transmission belt / wheel: Chinese top brand. 4) Cutting wheel / wheel clamp: German import BOHLE brand. | 1) Flannel: black fiber felt 2) Working table board: High-density fiberboard. 3) Top rod: 2 in horizontal and 1 in longitudinal |

Technical Data | 1) Loading glass size range: Minimum size: 1500x1300mm Maximum size: 7000x1300mm 2) Thickness of glass: 3-19mm. 3) Loading cycle: 40-60 seconds (adjustable) 4) Transmission speed: 0-40m/min (adjustable) 5) Maximum suction depth: 650mm 6) Maximum loading weight: 1200 Kgs 7) Number of loading arms on one side: 6 arms. 8) Number of single-arm suction cups: 4. 9) Loading flip arm: single flip 10) Loading work station: single station 11) Installation power supply: 380V/50HZ (special conditions can be adjusted according to customer requirements) 12) Installation Power: 8KW 13) Compressed air: 0.3Mpa-0.5Mpa 14) Vacuum pressure: -70~ -90Kpa (adjustable according to glass thickness) | 1) The maximum cutting size: 7000x1300mm 2) Workbench height: 900±30mm. 3) Cutting thickness: 3-19mm 4) Straight line parallelism: ≤±0.25mm/m 5) Diagonal accuracy: ≤±0.5mm/m (the above accuracy is based on the accuracy of the cutting line before strip) 6) Cutting bridge speed: 0-180m/min. (Adjustable) 7) Cutting bridge acceleration :≥3.0m/s2 8) Blade speed: ≥180m/min 9) Blade acceleration: ≥6.0m/s2 10) Belt conveying speed: ≥40m/min 11) Cutting head positioning accuracy error: ≤±0.2 mm 12) Installation power supply requirements: 380V/50HZ 13) Actual power of the equipment: 8KW 14) Compressed air: 0.6 MPA 15) Total weight: 3T | 1) Working table size: 7000x1500mm 2) Working table height: 900±30mm (or according to customer requirements) 3) Number of fans: 1 (independent switch control) |

This is Helen from Perfect Laser. Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net